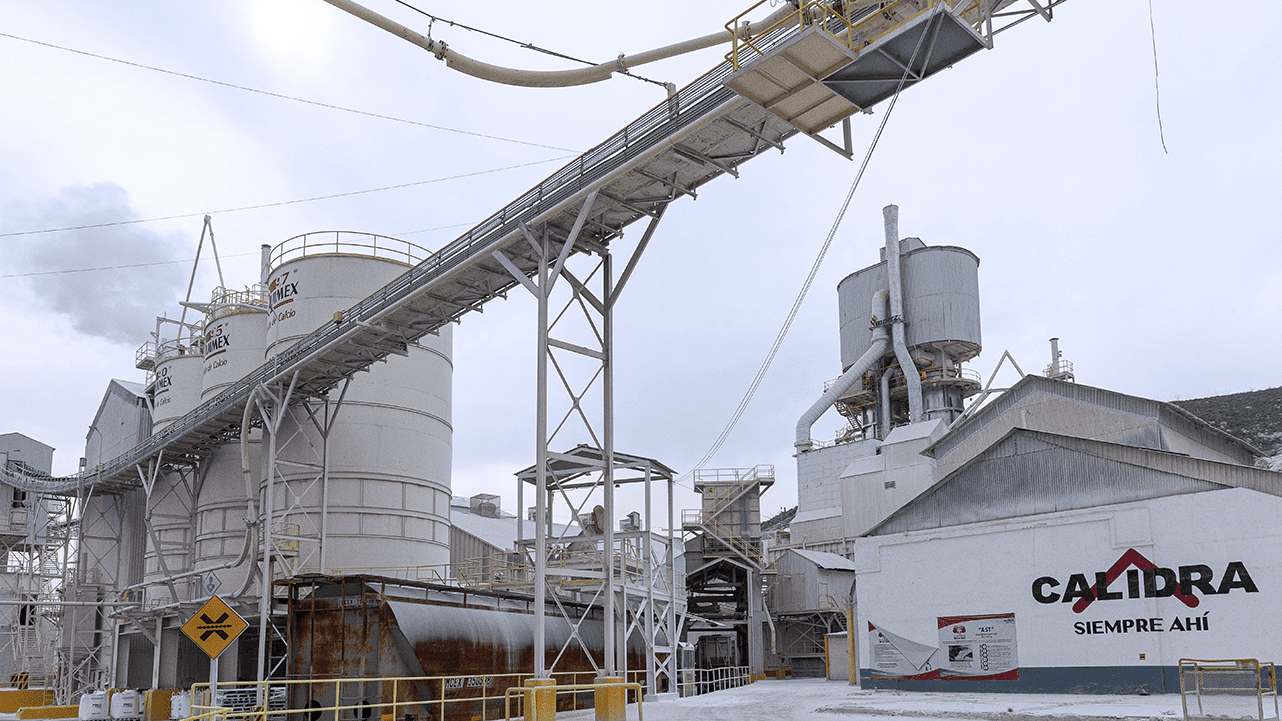

Lime in the chemical industry

The lime benefits industrial processes and facilitates the creation of specialized products. Within the chemical industry, lime is used as raw material in various processes. Grupo Calidra has developed specialized products such as Quimex 90, Quimex 95, Quimex 97, Curtical, Magnicalcio and Tecnicalcio that participate in the production processes of different industries.

LIME FOR GLASS

In its production, lime allows the heating, melting, molding, and blowing of glass. It making the glass have better characteristics such as greater transparency, greater hardness, more brightness, and better color. The fusion is faster, which means economic savings and increased productivity in the glass manufacturing process.

LIME IN THE TANNING OF LEATHER

Curtical plays a fundamental role in the tanning of animal leather since it has different functions such as swelling of the leather to facilitate the removal of hair, increases alkalinity by regulating the pH, disinfects and moisturizes the skin, prevents bad odors and facilitates the elimination of some unwanted proteins and fats in the tanning process.

LIME IN PAPER PRODUCTION

In paper manufacturing, lime participates as a purifier and bleacher of cellulose pulp. Likewise, it increases the quality of the paper and helps regulate its brightness, color, and texture.

LIME IN SOAP PRODUCTION

In soap making, lime hydrolyzes fat esters, forming a long-chain salt, with a hydrophilic part and a hydrophobic part. Which allows the separation of fats.

LIME IN PHARMACEUTICAL PRODUCTS

Lime participates as an additive in the manufacture of toothpaste.

It is used as an excipient for some medications, as well as in some hair removal products.

LIME IN RUBBER PRODUCTION

Lime has two main functions in rubber production: removing possible moisture excess, and accelerating the vulcanization reaction.